Byimbitse murwego rwo gutanga, abapfumu bamwe bahindura umucanga mo disiki nziza ya diyama yubatswe na sisitemu ya kirisiti ya kirisiti, ningirakamaro kumurongo wose utanga igice. Biri murwego rwo gutanga amasoko yongerera agaciro "umucanga wa silicon" inshuro zigera ku gihumbi. Umucyo ucye ubona ku mucanga ni silicon. Silicon ni kirisiti igoye ifite ubwitonzi kandi bumeze nkicyuma (ibintu byuma kandi bitari ibyuma). Silicon iri hose.

Silicon nikintu cya kabiri gikunze kugaragara kwisi, nyuma ya ogisijeni, nibintu bya karindwi bikunze kugaragara mubisanzure. Silicon ni kimwe cya kabiri, bivuze ko ifite amashanyarazi hagati yabatwara (nk'umuringa) na insulator (nk'ikirahure). Umubare muto wa atome zamahanga mumiterere ya silicon zirashobora guhindura muburyo bwimyitwarire, bityo ubuziranenge bwa silicon-semiconductor yo mu rwego rwo hejuru bugomba kuba hejuru cyane. Ubuziranenge bwemewe bwa silicon yo mu rwego rwa elegitoronike ni 99.999999%.

Ibi bivuze ko atome imwe gusa itari silicon yemerewe kuri atome miliyari icumi. Amazi meza yo kunywa atuma miriyoni 40 zidafite amazi ya molekile, zikubye inshuro miriyoni 50 ugereranije na silicon yo mu rwego rwa semiconductor.

Uruganda rwa silicon rwuzuye rugomba guhindura silikoni-yuzuye cyane muburyo bumwe. Ibi bikorwa mugutangiza umubyeyi umwe kristu muri silicon yashongeshejwe mubushyuhe bukwiye. Mugihe kristu nshya yumukobwa itangiye gukura hafi ya kristu ya nyina, ingirangingo ya silicon ikora buhoro buhoro ivuye muri silikoni yashonze. Inzira iratinda kandi irashobora gufata icyumweru. Ingoti ya silicon yarangiye ipima hafi kilo 100 kandi irashobora gukora wafer zirenga 3.000.

Wafers yaciwemo uduce duto ukoresheje insinga nziza ya diyama. Ubusobanuro bwibikoresho byo gukata silikoni ni hejuru cyane, kandi ababikora bagomba guhora bakurikiranwa, cyangwa bagatangira gukoresha ibikoresho kugirango bakore ibintu byubusa mumisatsi yabo. Intangiriro ngufi kubyerekeranye na silicon wafers iroroshye cyane kandi ntabwo ishimira byimazeyo umusanzu wubwenge; ariko twizeye gutanga ibisobanuro kugirango twumve neza ubucuruzi bwa silicon wafer.

Isoko ryo gutanga no gukenera wafer ya silicon

Isoko rya wafer isoko ryiganjemo ibigo bine. Kuva kera, isoko ryabaye muburyo bwiza hagati yo gutanga nibisabwa.

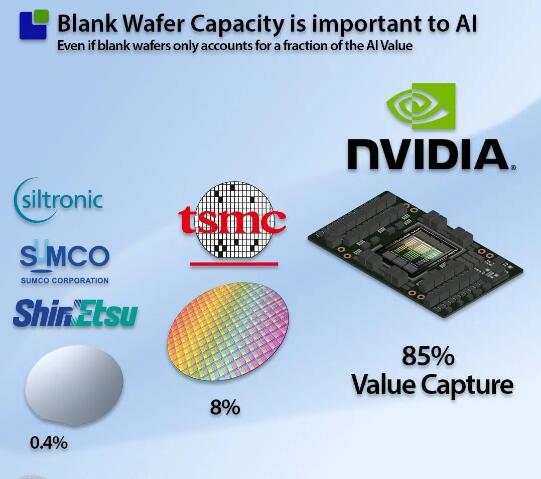

Igabanuka ry’igurisha rya semiconductor mu 2023 ryatumye isoko iba mu bihe birenze urugero, bituma ibicuruzwa biva mu mahanga byinjira mu gihugu ndetse no hanze. Ariko, ibi nibintu byigihe gito. Mugihe isoko rimaze gukira, inganda zizahita zisubira mubushobozi kandi zigomba kuzuza ibyifuzo byinyongera bizanwa na revolution ya AI. Inzibacyuho kuva gakondo ya CPU ishingiye kubwubatsi bwihuse bizagira ingaruka ku nganda zose, kuko, ariko, ibi birashobora kugira ingaruka ku bice biri hasi yinganda zinganda.

Igishushanyo mbonera (GPU) imyubakire isaba agace ka silicon

Mugihe ibyifuzo byimikorere byiyongera, abakora GPU bagomba gutsinda imbogamizi zogushushanya kugirango bagere kumikorere ihanitse kuva GPUs. Biragaragara, gukora chip nini nuburyo bumwe bwo kugera kumikorere ihanitse, nkuko electron zidakunda gukora urugendo rurerure hagati ya chip zitandukanye, zigabanya imikorere. Ariko, hariho imbogamizi ifatika yo gukora chip nini, izwi nka "retina limit".

Imipaka ya lithographie yerekana ubunini ntarengwa bwa chip ishobora kugaragara mu ntambwe imwe mu mashini ya lithographie ikoreshwa mu gukora semiconductor. Iyi mbogamizi igenwa nubunini ntarengwa bwa magnetiki yumurima wibikoresho bya lithographie, cyane cyane intambwe cyangwa scaneri ikoreshwa mugikorwa cya lithographie. Kubuhanga bugezweho, imipaka ya mask isanzwe igera kuri milimetero kare 858. Ingano ntarengwa ningirakamaro cyane kuko igena ahantu hanini hashobora gushushanywa kuri wafer mugihe kimwe. Niba wafer ari nini kurenza iyi mipaka, hazakenerwa byinshi kugirango ushushanye neza wafer, ibyo bikaba bidashoboka kubyara umusaruro mwinshi kubera ibibazo bitoroshye. GB200 nshya izatsinda iyi mbogamizi muguhuza ibice bibiri bya chip hamwe nubunini buke bugabanijwe muri silicon interlayer, bigakora super-particle-limited substrate ikubye kabiri. Ibindi bigarukira kumikorere ni ingano yo kwibuka hamwe nintera kuri ubwo kwibuka (ni ukuvuga umurongo wa memoire). Imyubakire mishya ya GPU yatsinze iki kibazo ukoresheje ububiko bwagutse bwagutse (HBM) bwashyizwe kumurongo umwe wa silicon hamwe na chipi ebyiri za GPU. Urebye kuri silicon, ikibazo na HBM nuko buri gice cya silicon yikubye kabiri icya DRAM gakondo kubera intera ndende-parallel isabwa kumurongo mwinshi. HBM kandi ihuza chip yo kugenzura muri buri gice, ikongera agace ka silicon. Kubara neza byerekana ko agace ka silicon gakoreshwa mububiko bwa 2.5D GPU bwikubye inshuro 2,5 kugeza kuri 3 zububiko gakondo bwa 2.0D. Nkuko byavuzwe haruguru, keretse niba uruganda rukora uruganda rwiteguye iyi mpinduka, ubushobozi bwa silicon wafer burashobora kongera gukomera cyane.

Ubushobozi bw'ejo hazaza bw'isoko rya silicon

Icya mbere mu mategeko atatu yo gukora semiconductor nuko amafaranga menshi akeneye gushorwa mugihe amafaranga make aboneka. Ibi biterwa ninganda zinganda zinganda, kandi amasosiyete ya semiconductor afite ikibazo cyo gukurikiza iri tegeko. Nkuko bigaragara kuri iki gishushanyo, abakora inganda za silicon benshi bamenye ingaruka ziyi mpinduka kandi bakubye hafi inshuro eshatu amafaranga yose yakoreshejwe mu gihembwe gishize. Nubwo isoko ryifashe nabi, ibi biracyahari. Igishimishije kurushaho ni uko iyi nzira imaze igihe kinini. Amasosiyete ya silicon wafer afite amahirwe cyangwa azi ikintu abandi badafite. Imiyoboro ya semiconductor ni imashini yigihe ishobora guhanura ibizaza. Ejo hazaza hawe hashobora kuba amateka yabandi. Mugihe tutajya tubona ibisubizo, hafi buri gihe tubona ibibazo byingirakamaro.

Igihe cyo kohereza: Jun-17-2024